Background image by Maxime Raynal, France - Orage PLN

Electric Discharges: Types, Effects & Guide

Overview

- Electric discharges are events where electricity flows through a medium, typically producing visible light, sound, and heat.

- Corona discharges produce a distinctive bluish-purple glow and are used in air purification systems. However, they can cause equipment to degrade if not properly controlled.

- Corona discharges produce a distinctive bluish-purple glow and are used in air purification systems. However, they can cause equipment to degrade if not properly controlled.

Understanding how electric discharges work can help people who are interested in electricity protect their equipment better and come up with new uses in lighting, manufacturing, and scientific research.

Understanding Electric Discharges: What It Means When Electricity Leaps

Electricity doesn’t always stay put. When an electric current suddenly flows through a medium where it normally doesn’t—like air, gas, or even a vacuum—we say that an electric discharge has occurred. This happens when the electric field gets strong enough to break down the insulating properties of the medium, creating a conductive path for electrons to flow.

When you get right down to it, electric discharges are all about the ionization of atoms or molecules. This happens when electrons are removed from their atoms, leaving behind positively charged ions and free electrons that speed up in the electric field. When these fast-moving particles hit other atoms, they cause a domino effect that can produce visible light, sound, heat, and electromagnetic radiation. This ionization process changes materials that are usually insulating into conductive plasma channels, letting current flow where it wouldn’t be able to otherwise.

Electric discharges are fascinating due to their omnipresence in both natural and man-made systems. Whether it’s the awe-inspiring lightning strikes that have enthralled mankind since the dawn of time, or the understated blue glow around high-voltage power lines on humid nights, these occurrences define our relationship with electricity. Grasping these discharges is not just a matter of academic interest—it’s a crucial part of designing secure electrical systems, developing innovative technologies, and safeguarding delicate electronic components from harm.

Types of Electric Discharges

Electric discharges can take on many different forms, depending on factors like the voltage, current, the configuration of the electrode, and the medium in which the discharge occurs. Each type has its own unique characteristics that make it useful for some applications and problematic for others. Here are the 11 types that anyone interested in electrical engineering should know about.

1. Corona Discharge: The Mysterious Glow

Corona discharge happens when a conductor with a high electric potential creates a powerful electric field that partially ionizes the air around it. Unlike more powerful discharges, corona usually creates a localized ionization region without forming a complete conductive path. This phenomenon is most common around conductors with small radii of curvature—like sharp points, edges, or thin wires—where electric fields naturally concentrate.

Corona electric discharge is visibly represented by a unique blue-violet glow, often accompanied by a hissing or crackling sound and the production of ozone. While it is visually appealing, corona discharge is a significant power loss in high-voltage transmission lines and can speed up the degradation of insulation materials. However, engineers have harnessed this phenomenon constructively in applications like photocopiers, air purifiers, and electrostatic precipitators, where controlled corona discharge helps capture airborne particles with remarkable efficiency.

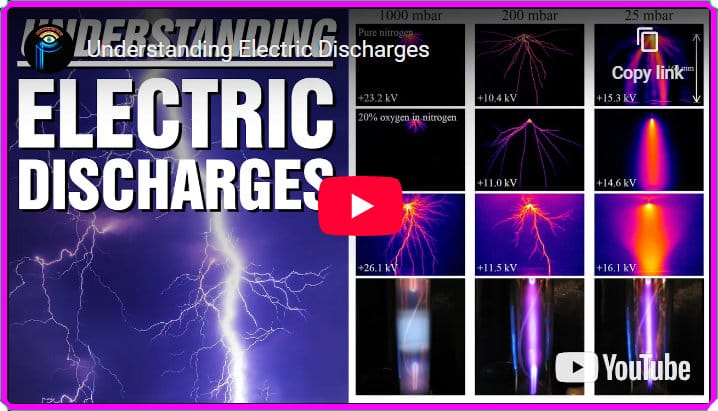

When considering a gas between two electrodes, it is important to note that—even without an applied potential—some of the gas molecules are continuously ionized by background radiation or cosmic rays. If a potential difference is applied across the electrodes, the resulting electric field causes these ions and electrons to drift toward the respective electrodes, producing a very weak current.

At this stage, the gas is only partially ionized. The electrons and ions do not yet have enough energy to cause further ionizing collisions, so recombination cannot occur. A small electric current flows, but it is too weak to be visible; this state is known as a dark discharge.

As the applied voltage increases, the electrons eventually gain sufficient energy from the electric field to cause further ionization through collisions. When this threshold is reached, a corona discharge begins.

When a gas is subjected to a sufficiently strong electric field, any free electrons present are accelerated by the field. As these electrons gain energy, they may collide with gas molecules and ionize them by dislodging loosely bound electrons. This produces additional free electrons along with positive ions, initiating an ionization cascade.

This process, when it occurs near sharp points or edges of conductors at high voltage, as in the above image of a spoon, a corona discharge occurs. It often appears as a bluish or violet glow in the air and emits light through the same basic mechanism as a gas discharge lamp—the excitation and de-excitation of gas molecules.

Corona electric discharge can occur in both positive and negative forms, depending on the polarity of the electrode where the discharge originates.

2. Brush Discharges

A dielectric is an insulating material that does not conduct electricity but can be polarized when exposed to an electric field. In such materials, the charges do not flow freely as in a conductor; instead, they shift slightly from their average positions. This polarization produces an internal electric field that opposes the applied field, thereby reducing the net electric field within the material. Because of this property, dielectrics are widely used in insulating applications—for example, in capacitors, where they allow the storage of electrical energy.

A brush discharge is related to a corona discharge but occurs under stronger electric field conditions. It appears when a high voltage is applied to an electrode surrounded by a dielectric medium, such as air. Instead of a uniform glow, it is characterized by multiple luminous, branching filaments or “streamers,” which are narrow plasma channels composed of ionized molecules from the dielectric.

These discharges arise when the electric field near the electrode exceeds the dielectric strength of the surrounding medium. In air, this threshold is approximately 30,000 volts per centimeter under standard conditions. At such field strengths, free electrons in the air are accelerated to velocities high enough to ionize neutral molecules upon collision. Each new electron can then trigger further ionizations, leading to an avalanche effect that produces visible streamers.

3. Streamer Discharges

Streamer discharges are a critical stage in dielectric breakdown, especially in the early development of long spark discharges. The process often begins with the formation of a corona discharge near the electrode experiencing the greatest electrical stress.

As the applied electric field increases, longer and colder filamentary discharges—known as streamers or sometimes burst corona discharges—emerge from the stressed electrode.

Streamers form when multiple electron avalanches coalesce into narrow conductive channels. Their rapid forward propagation is sustained by photon emission, which liberates new electrons ahead of the streamer tip. This mechanism enables streamers to rapidly extend into previously non-ionized regions of the gas. In doing so, streamers temporarily redistribute charge in the surrounding medium, creating localized regions of excess positive or negative charge.

If the electric field is sufficiently strong, many streamers can merge. Their combined currents heat the gas and create a highly conductive plasma channel, which bridges the gap between electrodes and develops into a spark discharge.

4. Leader Discharges

A leader discharge is a hot, highly conductive plasma channel that develops during dielectric breakdown in long spark discharges. The elongated plasma channel is known as a leader, and its electrical conductivity can approach that of an arc.

The leader acts to project the electric field from the electrode deeper into the gap. At the tip of the leader, intense fields create conditions for new streamer discharges, which extend even farther into the surrounding medium.

As successive streamers feed into the leader tip, the applied current maintains the channel’s high temperature and conductivity. With increasing voltage, the leader advances in discrete steps, progressively lengthening until it bridges the electrode gap.

While leaders are most commonly associated with the formative stages of a lightning stroke, they are a fundamental feature in the development of all long spark discharges.

5. Glow Discharge: The Magic Behind Neon Signs

Glow discharge is a lower-energy, more stable type of electric discharge that happens when you apply a moderate voltage across a gas at low pressure. This process creates a unique glowing light as electrons excite gas molecules, which then emit photons as they return to their normal state. Unlike the intensely concentrated arc discharge, glow discharge spreads itself more evenly throughout the gas volume, creating the familiar soft light we see in neon signs and fluorescent lights.

When you look at a glow discharge, you’ll notice that there are several different sections between the anode and the cathode, each with its own electrical properties and visual aspects. The brightest part of this is the “negative glow” region. The color of this glow is determined by the gas that is being used—neon gives off the famous red-orange light, argon gives off blue, and mercury vapor gives off ultraviolet light that can excite phosphor coatings to produce white light. Because the gas composition determines the emission spectra, glow discharge is a great tool for spectroscopy and material analysis.

Aside from lighting, glow discharge is also vital in plasma processing methods for the production of semiconductors, thin film deposition, and the modification of material surfaces. Engineers can control the discharge parameters to manipulate the energetic ions within the plasma. This allows them to clean, etch, or deposit materials at the molecular level. As a result, they can create increasingly complex microelectronic components.

A glow discharge is a plasma formed when an electric current passes through a gas at reduced pressure. It is typically produced by applying a voltage between two electrodes inside a sealed tube containing a low-pressure gas.

When the applied voltage exceeds a critical value known as the striking voltage, ionization of the gas becomes self-sustaining, and the tube emits a characteristic colored glow determined by the gas species.

Conduction in the gas requires charge carriers—electrons and ions—produced by the ionization of gas molecules. Electrons emitted from the cathode are accelerated by the electric field to velocities high enough to ionize additional gas molecules upon collision. This initiates an avalanche process, where each electron can generate more electrons and ions, sustaining the discharge.

As the discharge current increases, a larger area of the cathode contributes to the glow. With further increases in current, the plasma transitions to a different conduction regime: an arc discharge, which is hotter, denser, and far more conductive.

Structure of a Glow Discharge

In a glow discharge tube, the plasma forms a series of alternating luminous and dark regions between the cathode and the anode. These arise because of variations in local electric fields, particle densities, and excitation processes within the gas. The main regions are:

Cathode Glow

- A thin luminous layer adjacent to the cathode.

- Caused by the excitation of gas atoms by positive ions striking the cathode surface.

Crookes Dark Space (Cathode Dark Space)

- A narrow dark region next to the cathode glow.

- Strong electric fields accelerate electrons here to high velocities, but the region appears dark because electrons have not yet undergone enough collisions to excite visible emission.

Negative Glow

- A bright luminous zone following the Crookes dark space.

- Here, electrons have gained enough energy to excite and ionize gas molecules, leading to strong visible emission.

Faraday Dark Space

- A dimmer region beyond the negative glow.

- Electrons have lost much of their energy in collisions, so visible excitation decreases.

Positive Column

- A long, luminous region extending toward the anode.

- Contains a relatively uniform plasma with a lower electric field strength.

- In long tubes, the positive column may show striations (alternating bright and dark bands) due to periodic variations in ionization and excitation.

Anode Glow and Anode Dark Space

- A faint glow and small dark region may appear near the anode, depending on operating conditions.

- These are less pronounced than the structures near the cathode.

Compare glow discharge with butterfly planetary nebulae like the Minkowski 2-9 Twin Jet Nebula in the constellation Ophiuchus:

6. Electrostatic Discharge: The Spark You Feel

Image credit: Pablo Andrés Ortega Chávez

Electrostatic discharge (ESD) happens when built-up static electricity suddenly moves between objects with different electrical potentials. This is what causes the small shock you may feel after walking on a carpet and then touching a doorknob. Even though this seems harmless in our daily lives, ESD is a big problem for electronic devices. Even a tiny spark that we can’t see can ruin sensitive semiconductor parts.

ESD is primarily caused by a process known as triboelectric charging. This is the separation of electric charges that happens when certain materials rub against each other and then separate. This process can create potential differences of more than 25,000 volts, although the electric current and duration are extremely low. When the discharge occurs, the fast flow of current can create electromagnetic pulses that can induce damaging voltages in nearby electronic circuits. The semiconductor industry spends billions of dollars every year on measures to prevent ESD. These include specialized packaging, grounding straps, ionizers, and environments where the humidity is controlled.

7. Townsend Discharge: The Starting Point

The Townsend discharge is the first step of the electrical breakdown in gases. It happens at a relatively low current before it turns into glow or arc discharges. This process was named after the physicist, John Sealy Townsend. It starts with a few naturally occurring free electrons that are accelerated by an electric field. As these electrons gain energy, they collide with gas molecules. This collision ionizes the gas molecules and releases additional electrons. This process is called an “electron avalanche.”

Townsend discharge is unique because it can sustain itself after reaching a certain point. This happens when positive ions hit the cathode with enough force to cause secondary electron emission. This creates a feedback loop that keeps the discharge going. This is also what sets the basic lower limit for gas breakdown voltage. This is the smallest amount of electric field needed to start a self-sustaining discharge in a certain gas at a specific pressure and gap distance. Knowing how Townsend discharge works is important when you’re designing gas-filled tubes, surge arresters, and vacuum interrupters, where you want a controlled breakdown.

8. Arc Discharge

An electric arc is a type of electrical breakdown of a gas that produces a sustained, high-current discharge. When current flows through a normally non-conductive medium, such as air, it ionizes the gas and creates a plasma. This plasma is highly conductive and emits intense visible light along with heat and ultraviolet radiation.

Unlike a spark discharge, which is brief and momentary, an arc discharge is continuous once established. A distinctive property of arcs is their negative resistance characteristic: as the current increases, the voltage across the arc decreases.

This behavior makes uncontrolled arcs dangerous. Once initiated, an arc can draw ever-increasing current from a fixed-voltage source, potentially damaging or destroying electrical equipment.

9. Vacuum Discharge

A vacuum discharge, or vacuum arc, can occur in a high-vacuum environment when an electrode surface begins to emit electrons. This emission may be triggered either by:

- Thermionic emission — when the electrode is heated sufficiently for electrons to escape the surface.

- Field electron emission — when an intense electric field pulls electrons directly out of the metal surface.

Once initiated, a vacuum arc can be self-sustaining. The liberated electrons are rapidly accelerated by the electric field and strike the electrodes with high kinetic energy. These impacts locally heat the cathode surface, often producing a tiny incandescent spot that releases additional charged particles. At sufficiently high currents, this process maintains the plasma and keeps the arc alive.

Under some conditions, an anode spot may also form, where intense heating of the anode surface contributes further to plasma generation.

10. Thermionic Arc Discharge

A thermionic vacuum arc discharge can be initiated under high-vacuum conditions between a heated cathode and an anode.

When the cathode is heated to a sufficient temperature, it emits electrons through thermionic emission. These electrons are then accelerated toward the anode by the applied electric field. As the electron beam strikes the anode, it deposits energy and raises the anode’s temperature.

At elevated temperatures, the anode begins to evaporate material atoms into the surrounding vacuum. Once a steady-state vapor density is established near the anode, and if the applied voltage is high enough, ionization of this vapor occurs. This triggers the formation of a bright, highly conductive plasma channel between the cathode and anode—an arc discharge.

The process is self-sustaining:

- Thermionically emitted electrons continue to bombard and heat the anode.

- The heated anode releases additional vapor.

- Ionization of this vapor provides the charge carriers needed to maintain the arc.

The resulting discharge is far more intense and luminous than the initial thermionic emission current, and its properties depend strongly on the cathode temperature, the anode material, and the applied voltage.

Thermionic Arc Discharge vs. Pure Vacuum Arc Discharge

Initiation Mechanism

Thermionic Arc Discharge:

- Requires a heated cathode to emit electrons via thermionic emission.

- The emitted electrons bombard the anode, causing it to heat and release vapor that sustains the discharge.

Pure Vacuum Arc Discharge:

- Does not rely on cathode heating.

- Triggered by field electron emission (from very strong electric fields at microprotrusions on the electrode surface) or by microexplosions at the cathode.

- Once electrons are emitted, local heating produces tiny cathode spots that supply plasma directly.

Role of the Anode and Cathode

Thermionic Arc:

- The cathode provides electrons thermionically.

- The anode plays a crucial role by supplying evaporated material, which becomes ionized and forms the plasma.

Vacuum Arc:

- The cathode is the dominant source of plasma.

- Cathode spots eject metal vapor and ions into the discharge; the anode is largely passive.

Plasma Formation

- Thermionic Arc: Plasma forms primarily from anode vapor released by heating from the electron beam.

- Vacuum Arc: Plasma forms mainly from cathode material ejected at cathode spots.

Sustainment

- Thermionic Arc: Sustained by continuous cathode heating (to emit electrons) and anode heating (to release vapor).

- Vacuum Arc: Sustained by cathode spots that continually emit both electrons and metal ions under strong local heating.

Applications

- Thermionic Arc: Used in specialized vacuum tubes, controlled plasma sources, and high-vacuum switching devices.

- Vacuum Arc: Common in high-current vacuum switches, vacuum circuit breakers, and in materials science for vacuum arc deposition (coatings and thin films).

11. Partial Discharge

A partial discharge is a localized dielectric breakdown that occurs in a small region of a solid or fluid electrical insulation system under high voltage stress. Unlike a complete breakdown, it does not fully bridge the gap between two conductors.

Partial discharges typically originate in imperfections such as voids, cracks, or inclusions within solid insulation, or in gas bubbles within liquid insulation.

They are generally non-sustaining events: once a localized plasma channel briefly forms and bridges the void, the local electric field is reduced. This collapse of the field causes the plasma to disperse, and the discharge ceases until conditions build up again to trigger a new event.

Over time, however, repeated partial discharges can degrade insulation by eroding material, producing chemical byproducts, and gradually extending the defect—eventually leading to full dielectric failure.

The main purpose of this article is to get you to critically think about what you see on a cratered celestial object, like the Moon:

According to the Electric Universe (EU) theory, craters are often not scars of impact, but the machining marks of cosmic plasma arcs. Laboratory discharges reproduce the same patterns—raised rims, central peaks, terraced walls, dendritic rilles—suggesting that planetary surfaces are electrical records of catastrophic events in a once more electrically active Solar System, not that long ago.

Partial discharges in the laboratory, when applied to rock, metal, or dielectric surfaces, produce pits, craters, and dendritic channels. Importantly, these features appear without the need for massive incoming projectiles. Instead, the electric arc itself does the excavation, removing material by ablation, melting, and ejecta deposition. Central peaks of craters are created as intertwined electric currents rotate and gouge away the material around the peaks.

According to EU postulates, Mars’ northern hemisphere was excavated by immense plasma discharge activity, leaving nearly two-thirds of the planet’s surface lying several kilometers lower than the southern highlands. The Martian southern hemisphere (the highlands) is rugged, heavily cratered terrain. The average elevation is 2–4 km higher than the mean planetary radius. Surfaces are much older, preserving the record of electrical activity. Where did the missing material go? The asteroid belt offers a compelling clue, along with the countless comets and meteoroids scattered throughout the Solar System.

The Deuteronilus Mensae region along the highland/lowland dichotomy boundary in the Northern hemisphere of Mars.

Apollo astronauts observed that lunar craters often appear strangely pristine, with little ejecta surrounding them—unlike what would be expected if they had formed solely by impact. Space probe encounters have since shown that comets are not “dirty snowballs,” but rocky bodies resembling asteroids. Many display curious dumbbell shapes, consistent with electrical machining rather than melting and refreezing of ice.

The Power of Lightning: Intense Electrical Discharge

When it comes to electrical discharges, nothing is more awe-inspiring or powerful than lightning. It is the most intense electrical discharge that most people will ever see in their lives. A single bolt of lightning can carry up to one billion volts and 30,000 amperes. The process starts with the separation of charges within storm clouds. Lighter, positively charged ice crystals rise to the top of the cloud, while heavier, negatively charged particles sink to the bottom.

When the potential difference between these charges becomes large enough (usually hundreds of millions of volts), a stepped leader of ionized air forms a conductive path from the cloud to the ground. Once this path connects with upward streamers from the ground, the main lightning strike happens, releasing an incredible amount of energy in just a few milliseconds.

Lightning can heat the air it passes through to an incredible 30,000°C, which is five times hotter than the Sun's photosphere. This sudden heating causes the air to expand rapidly, producing the thunderous shock wave. In addition to its raw power, lightning is a key player in the Earth’s nitrogen cycle. It helps to fix nitrogen from the atmosphere into a form that plants and other organisms can use. For electrical engineers, lightning is both a problem to be solved in the design of protection systems and a source of inspiration in the development of high-energy switching technologies.

Electric Arc: The Powerful Electricity Bridge

Electric arcs occur when current travels through ionized gas between two conductors. In contrast to corona discharge, arcs make a complete, highly conductive plasma channel that can withstand very high current densities. The arc starts when a high voltage breaks down the gap between electrodes, ionizing the gas in between. Once it’s started, the arc can keep going at much lower voltages because of the highly conductive nature of the plasma path.

Electric arcs are known for their intense brightness and high temperature (up to 20,000°C), and they can keep going as long as there is enough current. This makes them useful for things like welding and cutting, where their concentrated heat can melt and join metals. But it also makes them dangerous in electrical equipment, where unintended arcs can cause catastrophic failures. The physics of how arcs form is complex. It involves things like thermal ionization, electron emission from electrodes, and plasma dynamics. Electrical engineers need to understand all of this to design safe switching equipment.

Understanding How Electric Discharges Develop in Various Conditions

When it comes to the creation of electric discharges, the characteristics of the medium in which the discharge takes place is key. Whether it’s in gases, liquids, or solids, the basic concept is the same: an electrical breakdown happens when the strength of the applied electric field is sufficient to speed up free electrons to the point where they can ionize more atoms or molecules. However, the details of this process can change greatly depending on the specific environmental conditions.

Discharge behavior is significantly influenced by environmental factors such as pressure, temperature, humidity, and the presence of impurities. For example, at high altitudes where atmospheric pressure is lower, the mean free path of electrons increases. This allows them to gain more energy between collisions and makes discharges more likely to occur at lower voltages. Similarly, high humidity can either promote or inhibit discharges depending on the specific configuration. Water vapor can increase air conductivity through ionization, but it can also sometimes prevent static charge buildup on surfaces.

How Gas Discharge Works

Gas discharge starts with free electrons that are already present in the gas due to things like background radiation or cosmic rays. When an electric field is applied, these electrons start moving toward the positive electrode, and they gain energy as they move. If they gain enough energy, they can ionize the gas molecules they hit, creating more free electrons and positive ions. This creates a plasma channel that can conduct electricity, allowing current to flow through the gas, which is normally an insulator.

The type of gas you use can greatly change the nature of the discharge. Noble gases such as neon and argon are relatively easy to ionize and produce unique emission spectra, which makes them perfect for lighting applications. On the other hand, electronegative gases like oxygen or sulfur hexafluoride capture free electrons to form negative ions, which increases the breakdown voltage and makes them useful as insulating media in high-voltage equipment.

Pressure is the most influential factor in gas discharge behavior, as evidenced by Paschen’s law. This law is an empirical relationship that demonstrates how breakdown voltage changes in relation to the product of pressure and gap distance. Interestingly, this relationship shows that both extremely high and extremely low pressures may necessitate higher voltages for breakdown than intermediate pressures. This explains why high-voltage equipment is safer to operate at either atmospheric pressure or in a hard vacuum, as opposed to intermediate pressures.

How the Electron Avalanche Works

The electron avalanche is the primary process that drives all gas discharges. It all starts with just one electron, which speeds up in an electric field until it has enough energy to ionize a gas molecule when it crashes into it. This collision causes another electron to be released, which means there are now two free electrons that can speed up and crash into other molecules. This process happens over and over again, each time creating more and more free electrons and ions. This is why it’s called an avalanche - because the number of free electrons and ions increases very quickly.

The avalanche mechanism explains the unexpected, quick transition from insulating behavior to conductive breakdown in gases. Mathematical models of this process show that under typical conditions, one electron can trigger an avalanche that makes thousands of charged particles within microseconds. The spatial development of these avalanches often follows branching, tree-like patterns called streamers, which gradually extend across the gap between electrodes.

What is a Breakdown Voltage?

Each insulating medium has a specific electric field strength, known as the breakdown voltage, at which it switches from an insulator to a conductor. In normal air conditions, this breakdown voltage is about 3 million volts per meter, but it can vary based on humidity, temperature, and the shape of the electrode. When the voltage across a gap is greater than this breakdown voltage, a discharge begins. This usually starts with tiny imperfections on the surface of the electrode where the electric field is concentrated.

The point at which electrical breakdown occurs isn’t a simple, linear relationship with the gap between electrodes, the shape of the electrodes, or the conditions in the environment around the electrodes. Sharp points can greatly reduce the voltage at which breakdown occurs, thanks to something called field enhancement. This is why you’ll typically see rounded surfaces on high-voltage equipment, to minimize unwanted discharges. In real-world applications, engineers have to apply safety factors to account for things like transient voltage spikes, contaminants, and the aging of insulation materials, all of which might lower the actual breakdown voltage over time.

When creating electrical systems, it is important to understand these thresholds. The systems must prevent unintended discharges, but also sometimes initiate controlled ones. The semiconductor industry, for example, needs to control breakdown thresholds very precisely. They manufacture integrated circuits with feature sizes that are almost the size of atoms. Even a tiny discharge event can destroy important components.

What Can We See When Electric Discharges Happen?

Electric discharges create a range of sensory experiences that have fascinated both scientists and the general public. The visual, auditory, and thermal effects of these discharges can help us understand the physical processes and energy conversions that occur when a discharge happens. By closely studying these effects, engineers can identify the type of discharge, determine how strong it is, and identify any potential dangers.

Many discharges have a visual impact that can be immediately recognized. Whether it’s the blinding flash of lightning or the subtle corona glow around high-voltage conductors, these light emissions are a result of excited atoms releasing energy as they return to their normal state. The length, intensity, color, and spatial pattern of this light can tell us a lot about how the discharge works, energy levels, and what the ionized medium is made of.

Why Do Electric Discharges Emit Different Colors?

The reason we see different colors in electric discharges is because of the specific emission spectra of excited atoms and molecules. When atoms in a gas are energized by colliding with high-speed electrons, their electrons move to higher energy states. As these electrons move back to their lower energy states, they emit photons with wavelengths that match the energy transitions—this is what creates the colors we see.

Neon is responsible for the well-known reddish-orange glow seen in signs, while mercury vapor primarily emits in the ultraviolet range. This requires phosphor coatings to change this invisible radiation into visible light in fluorescent tubes. Nitrogen, the main component of air, contributes blue-violet emissions to lightning and spark discharges. The exact analysis of these emission spectra through spectroscopy is a powerful tool for identifying the chemical composition of unknown materials.

Not only does color play a role, but the way light spreads during discharges can also provide key insights into the distribution of the field and the mechanisms of discharge. Corona shows up as a scattered light around areas with high fields, whereas arc discharges focus bright light along narrow, frequently unpredictable channels. These visual cues assist engineers in identifying issues with high-voltage equipment and developing more efficient technologies based on discharge.

Making Noise with Electric Discharges

Electric discharges create a variety of sounds, from the quiet sizzle of corona to the deafening blast of a lightning bolt. These noises come from the quick heating and expansion of gas in the discharge channel. When current flows through the ionized path, it heats the gas almost immediately. This causes the gas to expand explosively, creating a pressure wave. This pressure wave is what we hear as sound.

The nature of the sounds made by discharges can give us hints about the type of discharge and how much energy it has. Corona discharges make a hissing or crackling noise, as they are made up of many small, intermittent discharges around sharp edges. Spark discharges make sharp, staccato cracks that are proportional to how much energy they contain. Arc discharges often make a continuous roaring or buzzing noise, as the plasma channel fluctuates and interacts with the air currents around it.

Creating Heat and Thermal Consequences

Electric discharges are most notable for their ability to generate extreme heat. Discharge channels can reach temperatures ranging from a few thousand degrees in glow discharges to over 50,000°C in high-energy arcs, which is hotter than the surface of the sun. This heat is produced by ohmic heating as the current flows through the plasma channel, which has relatively high resistance, and by the release of binding energy when ions and electrons recombine.

Discharges are used in cutting, welding, and material processing due to their thermal effects, which can melt even the toughest materials. However, these same thermal effects can cause uncontrolled discharges to be incredibly damaging to electrical equipment. For example, arc faults can vaporize metal, ignite insulation, and create pressure waves strong enough to break enclosures when they occur inside switchgear or transformers. This shows why arc-fault detection and suppression systems are so crucial in modern electrical installations.

Thermal imaging is a useful method for detecting the early stages of discharge activity before it leads to disastrous failure. Even partial discharges with low energy produce localized heat that can be detected using sensitive infrared cameras. This allows maintenance technicians to find and fix potential failure points before they become bigger problems.

Real World Uses of Electric Discharges

Engineers often have to work hard to prevent unwanted electric discharges, but when they are controlled, electric discharges can power a wide range of technologies that have changed modern society. By carefully managing discharge parameters like current, voltage, duration, and medium, we can use these energetic phenomena for applications that range from everyday lighting to sophisticated manufacturing processes.

Discharge applications are versatile because of their unique capabilities. They can generate specific wavelengths of light, precisely erode materials, create reactive chemical species, and deliver controlled energy to otherwise inaccessible locations. As our understanding of discharge physics has advanced, so too has our ability to engineer these phenomena for increasingly specialized and demanding applications.

1. Lighting Technologies

Electric discharge lighting is one of the oldest and most widespread uses of controlled discharge phenomena. From the early carbon arc lamps that lit up the streets of the 19th century to the modern high-intensity discharge lamps that light up stadiums and highways, these technologies take advantage of the efficient light emission characteristics of plasma. Fluorescent tubes use low-pressure mercury vapor discharges to produce ultraviolet radiation that excites phosphor coatings, producing visible light that is up to five times more efficient than incandescent bulbs.

High-intensity discharge (HID) lamps, such as metal halide, high-pressure sodium, and mercury vapor lamps, use high-pressure discharges to achieve greater efficiencies and light output. These lamps include specific metal salts in the discharge medium, customizing the emission spectrum for specific applications—sodium for high-efficiency yellow light in street lamps, or metal halides for the bright white light required in retail and sports venues.

Despite the rise of solid-state LED lighting taking over discharge lamps in many areas, there are still some applications where discharge light sources are essential. For example, Xenon short-arc lamps are used in IMAX projectors and searchlights due to their ability to provide intense point-source illumination. Additionally, specialized spectral discharge lamps are used as calibration standards for scientific instruments.

2. Electrical Machining Processes

Electric discharge machining (EDM) uses the power of concentrated sparks to accurately shape conductive materials that would be challenging or impossible to machine using traditional methods. In this process, a controlled series of spark discharges between a tool electrode and workpiece removes material by vaporizing small parts of the surface. The workpiece and electrode never touch physically, which removes mechanical stresses and allows the machining of hardened steels, carbides, and other ultra-hard materials.

Today’s EDM systems have remarkable precision, with positioning accuracies of less than one micrometer and surface finishes that are almost as smooth as a mirror. This makes EDM a must-have for making injection molds, precision medical parts, and aerospace parts with complicated shapes. Wire EDM, a type that uses a continuously moving wire as the electrode, can cut complex shapes through materials up to 300mm thick while keeping tolerances measured in microns.

3. Plasma Cutting and Welding

Plasma cutting is a process that uses a high-temperature, high-speed plasma jet created by an electric arc that is constrained within a nozzle. This concentrated plasma stream can reach temperatures above 20,000°C and can melt metal almost instantly. The high-speed gas flow then blows the molten material away. Modern plasma cutting systems can cut through conductive materials up to 150mm thick at speeds over 10 meters per minute. This makes them invaluable for industrial fabrication.

Plasma arc welding is an advanced version of traditional arc welding that gives you more control over heat input and penetration. It works by using a specialized nozzle to constrict the arc, which dramatically increases the energy density. This allows for deeper penetration, narrower welds, and smaller heat-affected zones. Plasma welding is especially useful for joining thin materials or making high-quality welds in critical applications, such as aerospace components and pressure vessels.

Companies like Hypertherm have pioneered advanced plasma systems that have transformed the metal fabrication industry. These systems, which are computer-controlled, provide precise cutting that not only reduces waste material but also decreases production time. Hypertherm’s HyPerformance Plasma technology is particularly noteworthy because it offers cut quality that is nearly as good as laser systems, but it is more versatile when it comes to different types of metals and their thicknesses.

4. Air Cleaning Devices

Corona discharge air cleaners use the chemical activity of plasma to neutralize contaminants in the air. When air flows through a controlled corona discharge area, high-energy electrons start chemical reactions that change harmful pollutants into safe compounds. Ozone, charged particles, and reactive oxygen species produced in the discharge area can break down volatile organic compounds, deactivate microorganisms, and precipitate particles.

Industrial-sized electrostatic precipitators use the same principles, but on a much larger scale, to remove up to 99.9% of particulate emissions from power plants and industrial processes. In these systems, a corona discharge gives an electrical charge to dust particles, which are then drawn to collection plates with the opposite charge. This technology has kept millions of tons of pollution from entering the atmosphere, greatly improving air quality near industrial facilities.

5. Tools for Scientific Research

Electric discharges are incredibly useful in many scientific fields. They are used in spark discharge sources to break down and ionize samples for mass spectrometry, which allows for the accurate determination of what elements are present. Glow discharge spectroscopy is a non-destructive way to analyze the surface composition and depth profiles of materials. This is especially important in the manufacture of semiconductors and research in metallurgy.

Controlled discharges are crucial in plasma diagnostic techniques, especially in fusion energy research. This is because understanding the behavior of high-temperature plasma is key to the development of practical fusion reactors. Moreover, pulsed electrical discharges are used in creating shock waves for lithotripsy, a medical procedure that non-invasively breaks down kidney stones into fragments small enough to pass naturally.

Electric discharges are becoming more and more useful in research as technology advances. With the development of power supplies, diagnostics, and computational models, we can now understand discharges better than ever before. Thanks to modern time-resolved spectroscopy, we can even observe how discharges change over incredibly short periods of time, down to the picosecond. This has allowed us to see things we never could before.

Risks of Electric Discharges

Electric discharges can be harnessed to power amazing technologies, but they can also pose serious risks to people and equipment if they occur unexpectedly. It’s crucial for anyone who works with electrical systems to understand these risks, whether you’re a hobbyist playing around with microcontrollers or a professional working on high-voltage transmission lines. The risks include not only the obvious danger of electric shock, but also less obvious hazards like the degradation of insulation and electromagnetic interference.

The risk management of natural discharge phenomena such as lightning is made even more complex by their unpredictability. Unlike engineered systems, which have predictable failure modes, natural discharges can occur without much warning and with a wide range of energy content. This unpredictability means that robust protective measures and conservative safety margins must be used when designing systems that may be exposed to potential discharge events.

Damage to Electrical Equipment

Electric discharges can cause severe damage to electronic equipment in a variety of ways. The extreme heat of arc discharges can liquefy conductors and turn insulation into vapor, while the pressure waves produced by rapidly expanding plasma can cause physical breakage of components. Even lower-energy electrostatic discharges can damage sensitive semiconductor devices by causing microscopic insulating layers or junction areas within integrated circuits to fail.

Partial discharges, which are localized breakdowns that don’t span the entire gap between conductors, are especially dangerous to high-voltage equipment. These discharges happen within small voids or at interfaces within insulation systems. They slowly wear away the surrounding material and release corrosive byproducts that speed up degradation. Eventually, this process results in catastrophic insulation failure, often after years of operation without any symptoms. Modern diagnostic techniques such as ultrasonic detection and dissolved gas analysis, can help detect partial discharge activity before it leads to complete failure.

Electric Discharges as Fire Starters

Electric discharges are a major cause of fires in electrical systems due to their intense heat. For instance, an arc flash, which is an electric discharge that occurs when there is a low impedance connection between two points in an electrical system, can generate enough heat to instantly set fire to anything combustible nearby.

On the other hand, lower-energy discharges, such as tracking, which is the formation of conductive carbon paths across insulating surfaces, can create a sustained source of heat that can ignite building materials over a longer period of time. The National Fire Protection Association has estimated that electrical arcing alone causes around 30,000 home fires in the United States each year.

Arc fault circuit interrupters (AFCIs) are a significant safety improvement. They are designed to detect the unique electrical signatures of arcing faults and disconnect power before a fire can start. Unlike conventional circuit breakers that only respond to overcurrent conditions, AFCIs analyze the waveform of the current for the characteristic patterns produced by dangerous arcs. The widespread use of these devices in residential and commercial buildings has significantly reduced the number of electrical fire incidents.

Health and Safety

When people come into contact with electric discharges, they can experience anything from a slight annoyance to a deadly accident. An electric shock happens when the current travels through the tissues in your body, which can mess up the electrical signals that control the rhythm of your heart and the muscles you use to breathe. How bad it is depends on how strong the current is, the path it takes through your body, and how long you’re in contact with it. Even just 50 milliamperes going across your heart can cause ventricular fibrillation, and larger currents can cause burns from heat and destroy your tissues.

In addition to the dangers posed by direct contact, electric discharges can also cause secondary hazards. These include intense ultraviolet radiation, which can damage the eyes (this is known as arc eye or welder’s flash), acoustic trauma caused by the explosive sounds of discharges, and the production of toxic gases when materials are vaporized during high-energy discharges. In industrial environments, arc flash events are particularly dangerous. They can generate temperatures that are four times hotter than the surface of the sun and can eject droplets of molten metal at ballistic speeds.

Current electrical safety standards stress a step-by-step approach to protection. This begins with designing systems to reduce the risks of discharges. Then, engineering controls such as insulation and barriers are put into place. Lastly, personal protective equipment is provided for workers who have to interact with equipment that could potentially be hazardous. To prevent injuries related to discharges, it’s crucial to properly assess risks and follow safety protocols.

Keeping Yourself and Your Gear Safe

Keeping yourself and your equipment safe from electric discharges means taking a multi-layered approach. This is because electrical discharges can start in several ways and cause a variety of damage. If you’re an electrical hobbyist or a pro, it’s important to understand how to protect yourself and your gear. The best way to do this is to combine preventative measures that lower the chances of a discharge with protective systems that limit the damage if a discharge does happen.

How to Ground Properly

Grounding is the first step in ensuring electrical safety and protecting against electric discharges. By creating a low-impedance connection to the earth, you can prevent dangerous voltage buildups on conductive surfaces, which could otherwise cause unexpected discharges. In homes, this starts with the main grounding electrode system, which connects to the earth through ground rods, water pipes, or concrete-encased electrodes. If you’re working with sensitive electronic equipment, you might need a supplementary grounding system, which provides dedicated, low-noise paths to the earth separate from power system grounds.

For grounding to work correctly, you need to pay attention to the size of the conductor, the quality of the connection, and the layout of the system. If the cross-section of the conductor is too small, it can create bottlenecks that limit the flow of fault current and stop protective devices from working as they should. In the same way, connections that have corroded increase resistance and make the ground system less effective. You can use specialized equipment to carry out regular tests and make sure the ground system is working correctly before any failures happen.

Devices for Surge Protection

Devices for surge protection (SPDs) are the first line of defense against transient overvoltages that could trigger discharges within equipment. These devices are made up of components—usually metal oxide varistors (MOVs), gas discharge tubes, or silicon avalanche diodes—that quickly switch from high to low impedance when voltage surpasses predetermined thresholds. This action safely directs surge energy away from sensitive equipment and into the grounding system, where it is safely dissipated.

When it comes to surge protection, a well-rounded plan of action involves a cascaded approach with several layers of protection. The primary protection is located at service entrances and deals with high-energy surges that come from lightning strikes or utility switching. Secondary protectors are found at distribution panels and point-of-use devices, offering increasingly sophisticated protection with quicker response times. This organized system ensures that each layer of protection deals with a suitable portion of the surge energy, which prevents any single device from being overloaded.

How to Stay Safe

When you’re dealing with systems that can produce dangerous electric discharges, personal protective equipment (PPE) is your last resort. This means you’ll need insulating gloves that can handle the right voltage levels, arc-rated clothes that put themselves out instead of catching fire, face shields that guard against both impact and radiation, and insulating tools that keep you from accidentally touching energized parts. The PPE you need depends on the arc flash hazard analysis, which figures out the potential incident energy at the distance you’re working.

While physical protection is important, it is also crucial to adopt safe work habits to prevent discharges. This means turning off equipment before working on it when you can, using insulated barriers to avoid accidentally touching live parts, keeping a safe distance from energized conductors, and not wearing conductive items such as metal jewelry when working around electrical equipment. The “Lock-Out/Tag-Out” procedures, which involve physically securing the disconnecting means and putting up warning tags, prevent the equipment from being accidentally turned back on during maintenance activities.

Methods for Protecting Equipment

One way to protect sensitive electronics from the electromagnetic pulses created by electric discharges is by using electromagnetic shielding. This type of shielding, usually made from conductive materials such as copper or aluminum, acts like a Faraday cage. It intercepts electromagnetic fields and conducts them to the ground before they can induce damaging voltages in the circuits that are being protected. However, for the shielding to be effective, the shield continuity must be maintained. This means that special care must be taken with cable entries and ventilation openings, as they could potentially compromise the integrity of the shield.

For machines working in environments where there is a high risk of electrostatic discharge, special coatings and materials can help to stop charge building up or provide controlled paths for the discharge. Anti-static films, conductive treatments for floors, and systems to control humidity all help to manage electrostatic potentials before they reach levels where they can cause damaging discharges. In the manufacture of semiconductors and other highly sensitive environments, comprehensive programs to control electrostatic discharge cover everything from the design of the facility to the clothing of the employees.

Another effective protection strategy is optical isolation, which uses light to transmit signals across potential discharge paths without providing a conductive connection. This approach completely blocks current flow during discharge events, protecting both equipment and operators. Modern fiber optic communication systems extend this principle to long-distance connections, providing inherent immunity to lightning-induced surges that would destroy conventional copper communications links.

How to Safely Watch Electric Discharges

Electric discharges are visually and acoustically stunning, making them interesting to watch and experiment with. But, their energetic properties can be dangerous. With the right safety measures and tools, electrical enthusiasts can watch these phenomena and learn more about the physical processes that cause them without getting hurt.

When watching electric discharges, the most important rule is to keep a safe distance and use barriers to protect yourself. The distance you need to keep depends on how much energy the discharge has. For tiny electrostatic discharges, you only need to wear something to protect your eyes. But for big, high-energy arcs, you might need to use special filters or watch through a video system. No matter what kind of discharge you’re watching, you always need to protect your eyes. That’s because many discharges give off very strong ultraviolet light.

Easy Home Experiments

There are a number of safe, low-energy electric discharges experiments that can be carried out at home using simple equipment. One example is a piezoelectric igniter from a barbecue grill, which creates small, controlled sparks when compressed. By sparking it near the opening of containers filled with different safe gases, such as helium from balloons, you can observe the color of the discharge. Another experiment involves rubbing a balloon on hair or wool to create static charges. These can produce tiny, harmless sparks when discharged through a metal object, demonstrating the principles of electrostatic discharge without any real danger.

If you’re a bit more advanced, you might want to build simple electrostatic generators like Wimshurst machines or Van de Graaff generators using materials you can easily find. These machines produce higher-voltage discharges, but the current levels are too low to cause serious injury when they’re used properly. That said, you should still be aware of potential dangers to pacemakers or other medical devices that are sensitive to electromagnetic interference. And you should never use this type of equipment near flammable materials or electronics that can be damaged by electrostatic discharges.

Proper Equipment for Viewing Electric Discharges

When observing electric discharges, it is important to use specialized viewing equipment to ensure safety. Welding filters, especially those rated for shade 10 or higher, are effective at protecting against the intense ultraviolet and visible light that arc discharges produce. For long-term viewing, digital cameras equipped with the right filters can be connected to display screens, allowing for detailed observation while keeping a safe distance from the discharge. High-speed photography can capture the step-by-step progression of phenomena like lightning leaders or spark branching patterns, revealing aspects of the discharge that are invisible to the naked eye.

If you’re watching a natural electric discharge event such as lightning, you should ensure you have suitable cover. The best place to be is inside a large building or a car with a metal roof, and you should stay away from any plumbing, electrical wires, or telephone lines that could potentially conduct the lightning’s electricity. If you’re observing in the open air, make sure you’re a safe distance away—at least 30 feet—from any tall objects that could be hit by lightning, and have a plan to get to cover quickly if the storm gets worse.

When to Seek Professional Help

Even though you can safely observe many discharge phenomena if you take the right precautions, some investigations should be left to the professionals. Experiments that involve power line voltages, large banks of capacitors, or high-energy discharge systems can be deadly and require specialized training, equipment, and facilities. Also, if your discharge research involves hazardous gases, vacuum systems under stress, or equipment that can generate a lot of X-ray radiation, you need professional supervision and the right safety infrastructure.

What’s Next for Electric Discharge Technology?

Electric discharge technology is quickly advancing, and its applications are expanding into a variety of fields, from medicine to aerospace. Atmospheric pressure plasma jets now make it possible to sterilize heat-sensitive medical instruments and treat living tissue without heat. This allows for faster wound healing through the controlled use of reactive discharge species. These cold plasma devices can kill bacteria without harming human cells, which could completely change the way antibiotic-resistant infections are treated.

Some of the most exciting applications of electric discharges can be found in the field of fusion energy research. Here, pulsed power systems are used to create conditions similar to those found in the cores of stars. The Z-machine at Sandia National Laboratories, for example, uses a large array of synchronized discharges to generate powerful magnetic fields. These fields compress plasma to the point where fusion can occur, albeit for only a few nanoseconds.

While we are still a long way from being able to generate sustainable fusion power, these discharge-driven systems are helping to advance our knowledge of high-energy-density physics. They are also leading to the development of new technologies that could have applications in a variety of scientific and industrial fields.

FAQs

Electric discharges often spark a lot of curiosity, whether you’re just a casual onlooker or a seasoned professional. Here are some answers to the most frequently asked questions about electric discharges, their features, and how to stay safe.

What makes electric discharges different colors?

The unique colors you see in electric discharges come from the atomic structure of the gases through which the discharge is moving. When the electrons in a discharge bump into gas atoms or molecules, they give off energy that excites the electrons in these atoms, pushing them to higher energy states. When these excited electrons come back down to lower energy levels, they give off photons with wavelengths that match the specific energy differences between states, which makes the colors we see.

Every element has a unique array of potential electron transitions, which results in a unique spectral fingerprint. Neon creates the well-known red-orange glow used in signs, while mercury vapor primarily emits ultraviolet radiation that must be transformed into visible light by phosphor coatings. Nitrogen, the main component of air, is responsible for the blue-violet emissions frequently seen in lightning and spark discharges. Hydrogen generates unique red emissions, while sodium produces the characteristic yellow-orange light of street lamps.

The color of the discharge medium is also influenced by its pressure and temperature, as they affect the rates of collision and energy distribution among particles. Electric discharges under high pressure usually produce more continuous spectra with broader emission bands, while discharges under low pressure show sharper spectral lines that correspond to specific atomic transitions. This relationship between the conditions of discharge and spectral characteristics makes optical emission spectroscopy a powerful tool for diagnosing those studying plasma physics and discharge.

Is it possible for electric discharges to happen in a vacuum?

Surprisingly, electric discharges can happen in a vacuum, but the process is very different from what happens in gases at atmospheric pressure. In a completely perfect vacuum with no particles at all, discharges wouldn’t happen. But in reality, all vacuum systems have some leftover gas molecules, and surfaces give off electrons through processes like field emission, thermionic emission, and photoemission. These processes can start and keep the discharge processes going.

Field emission is the most important vacuum discharge mechanism, where powerful electric fields yank electrons directly from the surfaces of conductors. These field-emitted electrons can knock more electrons loose through secondary emission when they hit the opposite electrode, or create X-rays that cause photoemission from other surfaces. These processes must be carefully controlled in high-vacuum systems used for particle accelerators and X-ray tubes to avoid unwanted discharges that can harm sensitive parts and disrupt operation.

What is the function of lightning rods in safeguarding buildings from electric discharges?

Lightning rods, or air terminals as they are technically known, serve to shield buildings by offering a preferred point of contact and a regulated route for the lightning current to safely reach the ground. This system is comprised of three key elements: air terminals (sharp rods that extend above the building), down-conductors (low-impedance routes to the ground), and ground electrodes (links to the earth). Contrary to common misconception, lightning rods do not “draw” lightning away from the area they are protecting. Instead, they simply intercept strikes that would have otherwise hit the building.

The lightning rod’s defense mechanism is based on the principles of charge and electric fields. When a thunderstorm is brewing and a stepped leader is coming down from the cloud, the lightning rod’s sharp points create a high electric field. This field ionizes and creates upward-reaching streamers. These streamers meet the downward leader and form the lightning channel. This channel is more likely to go to the rod than to other parts of the building. The current then takes the path of least resistance - the low-impedance down-conductor. This is instead of taking unpredictable paths through the building that could start fires or damage the structure.

Can all electric discharges harm people?

Not all electric discharges poses the same threat to people. The risk is mainly based on the amount of current that could potentially flow through the body, which depends on the voltage, available energy, and path of the discharge. Everyday static electricity discharges may involve thousands of volts, but usually involve minimal current and energy—causing momentary discomfort without lasting harm. In contrast, even lower-voltage household electricity can be deadly if it provides sustained current flow through vital organs.

How are AC and DC electric discharges different?

AC (alternating current) and DC (direct current) electric discharges behave differently because their electric fields are fundamentally different. DC electric discharges have an electric field that always points in the same direction, so they have clearly defined anode and cathode regions that play consistent roles in the discharge process. This consistency allows things like cathode spots and anode falls to fully develop. DC arcs usually stay attached to the same points on electrodes until something forces them to move.

Unlike DC electric discharges, AC discharges have a field reversal at the supply frequency, usually 50-60Hz, which continuously changes the roles of electrodes. This change affects the movement of ions and electrons within the discharge, creating unique ignition and extinction transients with each half-cycle. In practical terms, AC arcs are typically less stable than DC arcs and require higher maintenance voltages to prevent extinction during current zero-crossings.

Challenge the standard model—explore the cosmos through the Electric Universe Theory. These Electric Constellations books contain full-color, data-rich investigations of four constellations each. They're not a beginner's star guide—they're a serious work for independent thinkers, astronomers, and scientifically literate readers seeking to understand the Universe beyond conventional gravity-based interpretations.

Each constellation is examined in detail, with attention to its Bayer-designated stars, mythological origins, meteor showers, and bordering constellations. In-depth profiles of deep-sky objects—including galaxies, planetary nebulae, and star clusters—are paired with high-resolution imagery from the Webb and Hubble space telescopes, delivering both scientific clarity and visual impact.

Central to this series is the Electric Universe (EU) model, which proposes that electromagnetic forces—not gravity alone—govern much of the structure and behavior of the cosmos. Rather than treating this as speculative fringe, the book frames the EU model as an evidence-based, plasma-physics-informed alternative to the standard cosmological narrative.

Inside each volume:

- Comprehensive coverage of four distinct constellations

- Analyses of deep-sky objects in the EU context

- Original commentary on plasma discharge features and Z-pinch configurations

- Mythological and historical context without romantic embellishment

Written for readers who demand more than rote repetition of gravitational dogma, Electric Constellations opens a new observational and theoretical frontier—where stars light by electrical currents, not fusion, and where structure emerges from plasma dynamics, not dark matter.

Whether you are an amateur astronomer, electrical engineer, or astrophysicist curious about alternative models, these books deliver a rigorous and visually stunning exploration of the night sky—illuminated by a very different current.